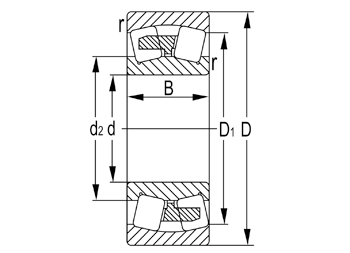

Spherical roller bearings have two rows of rollers, a common spherical outer ring raceway and two inner ring raceways inclined at an angle to the bearing axis. The center point of the sphere in the outer ring raceway is located on the bearing axis. Therefore, these bearings are self-aligning and insensitive to misalignment of the shaft with respect to the housing, which may be caused by, for example, shaft deflection. Spherical roller bearings are designed to withstand large radial loads and large axial loads in both directions.

Symmetrical Roll

The symmetrical rollers are self-adjusting to provide optimal load distribution along the length of the rollers. This can maintain low stress under all load conditions and extend the life of the bearing.

Roller tolerance

The rollers in spherical roller bearings are made extremely compact in size and have certain shape tolerances. Each roller is actually the same in size and shape as the other rollers in the group. This optimizes the load distribution on the rollers, thereby maximizing the life of the bearing.

Special roller profile

The roller profile determines the stress distribution in the roller/raceway contact area. The special profile makes the load more evenly distributed along the rollers and prevents stress peaks at the ends of the rollers, thus prolonging the life of the bearing.

Self-guide roller and floating guide ring between two rows of rollers

The self-guide roller reduces friction and frictional heat. The floating guide ring guides the unloaded rollers so that they enter the loading area in the best position.

Shandong Meizhou Precision Bearing Co., Ltd.

© 2022 Shandong Meizhou Precision Bearing Co., Ltd.. All rights reserved. | Sitemap